About RebusFarm

RebusFarm was founded in Cologne, Germany in 2006.

The render farm aims at fulfilling the growing need of rendering power in the field of 3D animation. RebusFarm supports all common 3D applications, including the host applications, as well as secondary rendering applications. Furthermore, RebusFarm targets to offer the largest possible rendering capacity at the most affordable price, while maintaining service oriented contact to the customer.

In 2009 RebusFarm presented a completely new and unique concept to integrate a render farm into the workflow of a 3D artist by publishing the Farminizer Software (patent pending). This revolutionary new concept gave the users full access to the power of the render farm from inside their own 3D software.

RebusFarm 2.0, which was released in February 2015, added the ControlCenter and the RebusDrop to the Farminizer. These two new components made the entire workflow even more intuitive and easy. The new ControlCenter allowed the users to manage and monitor their render jobs independently and from everywhere. Additionally, a few other features like secure file transfer, faster project export and automatic updates were added to the software on the render farm.

In September 2019 RebusFarm released the latest software innovation, RebusFarm 3.0. With a completely new design of the ControlCenter and features such as batch rendering/takes, pre-upload, a new preview and a resubmission function, the previous software version was raised to a completely new level.

Today RebusFarm is the market leader in terms of capacity, price, reliability and delivery speed, while continuously developing and researching new technologies to improve the render farm service even further.

Render Farm Hardware

We always use the newest hardware, because we know exactly what you need: Pure computing power. Get the full render farm power for every render job.

500 i9 x 18 x 2.60 GHz = 23,400.00 GHz

2000 XEON x 10 x 2.20 GHz = 44,000.00 GHz

Provided Hardware of Rebus Render Farm

Total Render Farm Power

- 92,360 GHz

- Cinebench: about 4.7 Mio.

- 465,664 cores

- 26,259 Octanebench

Server Type A

- AMD Threadripper 3970X

- 32 x 3.7 GHz

- 128 GB RAM

Server Type B

- Intel i9-7980XE (18core)

- 18 x 2.6 GHz

- 64 GB RAM

Graphics Processing Unit (GPU Render Farm)

- Latest GPUs, each with 217 Octanebench

Operating System

- Win 10

Render Farm - Green Power

Sustainable Render Farm Service

Green Power at Rebus Render Farm

CO2-free power from regenerative energy sources and energy-optimized technology

Climate protection and energy efficiency are two important subjects for one of the world's largest render farms. By constantly increasing the capacity of our render nodes, not only do we reach a higher cost-efficiency for our customers, but we are lowering the energy consumption per rendering hour as well. Furthermore, we are acquiring our power as green electricity from the DREWAG - Stadtwerke Dresden GmbH. This award-winning green electricity is produced from 100% CO2 and atomic waste free energy sources. The energy consists of pure water energy. Adding to that RebusFarm stands up for the expansion of production capacities for regenerative electricity, and its share in the energy mix to get increased. In the highly competitive market of render farms, this climate-friendly approach is ground-breaking.

Climate protection and energy efficiency are two important subjects for one of the world's largest render farms. By constantly increasing the capacity of our render nodes, not only do we reach a higher cost-efficiency for our customers, but we are lowering the energy consumption per rendering hour as well. Furthermore, we are acquiring our power as green electricity from the DREWAG - Stadtwerke Dresden GmbH. This award-winning green electricity is produced from 100% CO2 and atomic waste free energy sources. The energy consists of pure water energy. Adding to that RebusFarm stands up for the expansion of production capacities for regenerative electricity, and its share in the energy mix to get increased. In the highly competitive market of render farms, this climate-friendly approach is ground-breaking.

Against cost explosion and growing energy consumption of Render Farms

Energy consumption and costs have grown, a tendency that will continue in the coming years. Costs for electricity turn out to be an essential factor in IT-structures of a render farm. That's why other render farms consistently choose cheap energy, produced by controversial nuclear power plants or the CO2-generating combustion of fossil fuels. But short-term saving of costs doesn't solve the problem: To be competitive in the long term, IT-service providers have to increase their energy efficiency. RebusFarm does this in three essential areas: hardware, cooling, and management software.

Highly efficient hardware lowers the energy consumption of a render farm

RebusFarm buys its hardware with a focus on the newest energy-saving technologies and only uses CPUs with high processing density, to optimize the energy consumption per rendering hour of its render farm. Thus superficially inexpensive technologies, like old dual- or even single-core CPUs, are already disqualified.

Cooling without air-conditioning

By running without the usage of air-conditioning in our render farm we are gaining an essential advantage in energy efficiency. An elaborate cooling concept of our nodes allows us to work without the energy guzzler no.1: the air con.

Intelligent render farm software management

Performance-optimized, custom-tailored render farm management software results in important but unobvious energy-savings. Not only does our intelligent software management protect our customers from nasty surprises with their rendering results, it also reduces unnecessary energy consumption of the render farm by avoiding redundant renderings. Our render farm development endeavors aim at the best possible efficiency to advantage both our customers and the environment.

Designing the future in an ecologically-minded way

Almost every year we achieve 25 percent energy-savings per render-hour. To continue with this trend we are constantly working on upgrading and developing new, energy-saving technologies in the render farm. This has a positive effect on the companies balance, the customer's purse as well as the environment. But that's not enough: Thanks to the GrundGrün Energie GmbH, we run on 100% CO2 and nuclear waste free energy, in spite of drastic price cuts for the customers. Hence it's obvious: When you choose RebusFarm, you are deciding environment-friendly render farm while saving hard cash.

RebusFarm energy identification

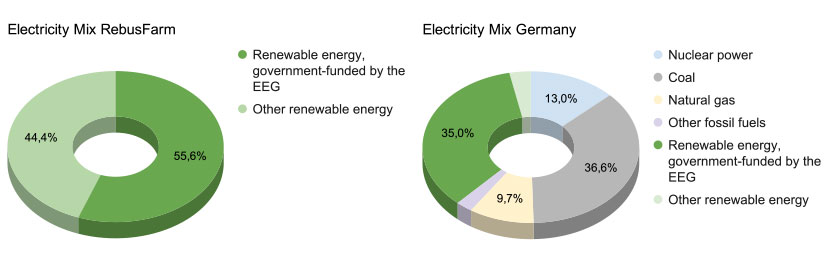

The green energy mix of our contractual partner is composed according to the chart. In comparison, you can see the average energy mix of other render farms on the right. Our CostCalculator includes a listing about how much carbon dioxide emission and atomic waste you will spare the environment with your current rendering job, compared to conventional render farms or rendering on your own machine.

The values show the origin of the electricity in accordance with § 42 of the energy industry act. They refer to the year 2019.

The values show the origin of the electricity in accordance with § 42 of the energy industry act. They refer to the year 2019.